The VFI is the interferometer of choice for industry leading photonics companies around the world. The VFI-1200 is an interferometric inspection system specifically designed for checking the surface quality and flatness of your cleaved or polished fibers. The VFI offers the perfect combination of a superb image quality with ease of use, and the reliability and robustness that our customers have come to expect from Arden products, resulting in fiber end face measurements that you can trust.

With the VFI, the user can view their fibers in a range of different views, both in 2D and 3D, allowing the user to get a full understanding of their cleaving or polishing process. It has therefore proven itself to be very well suited to Research, Production, or QA environments.

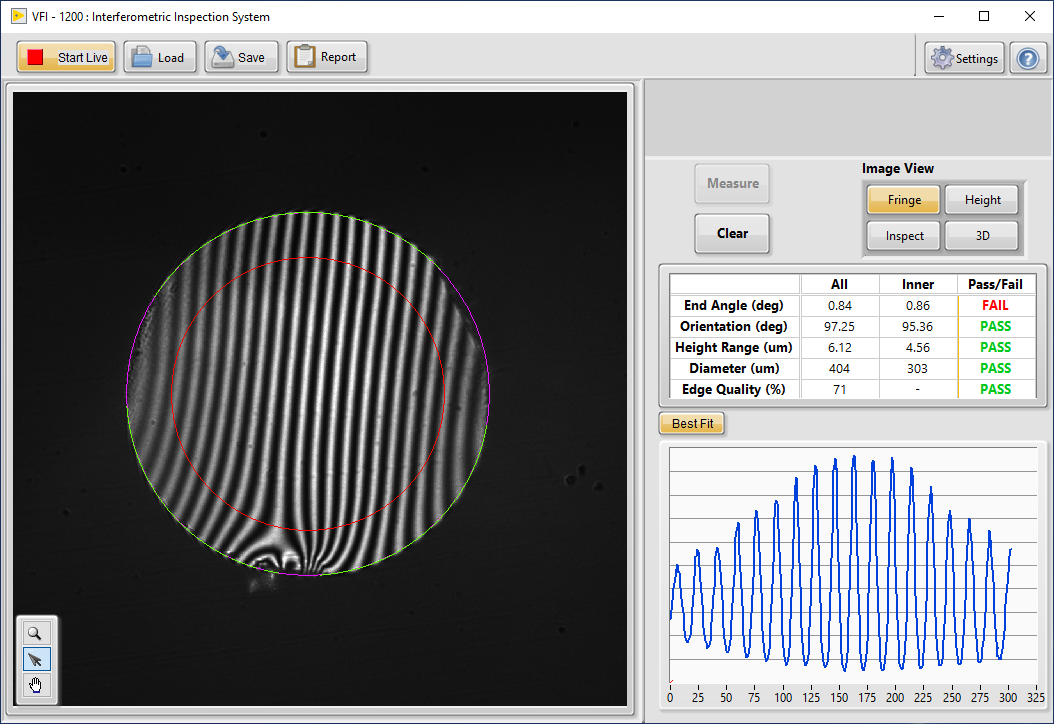

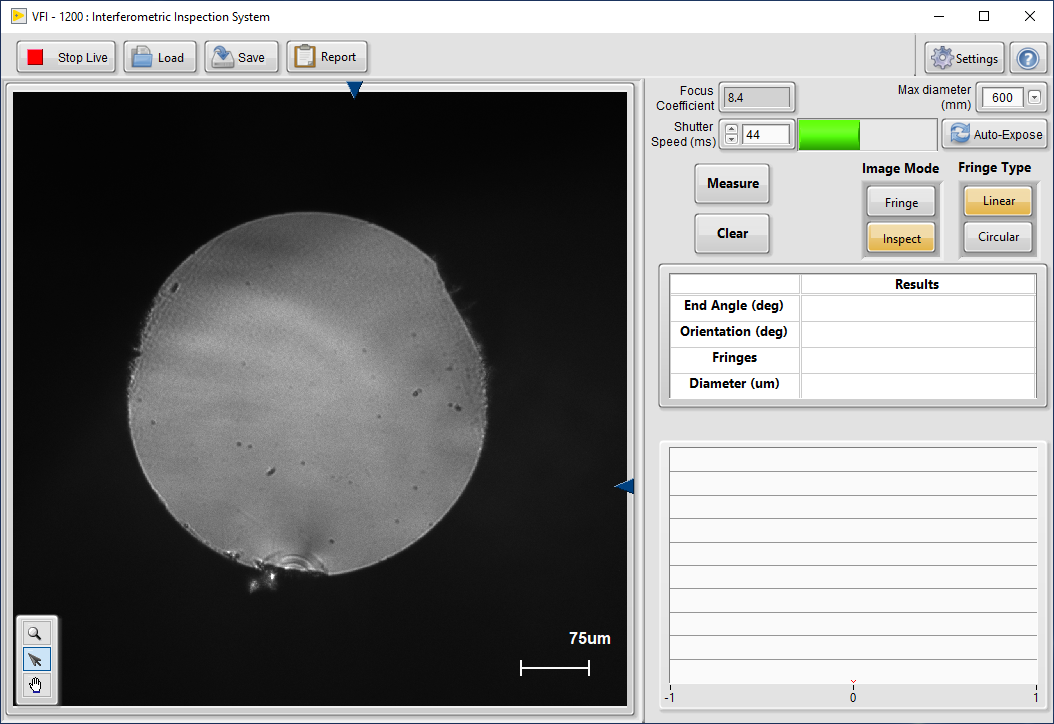

2D Mode

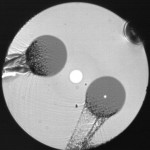

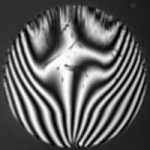

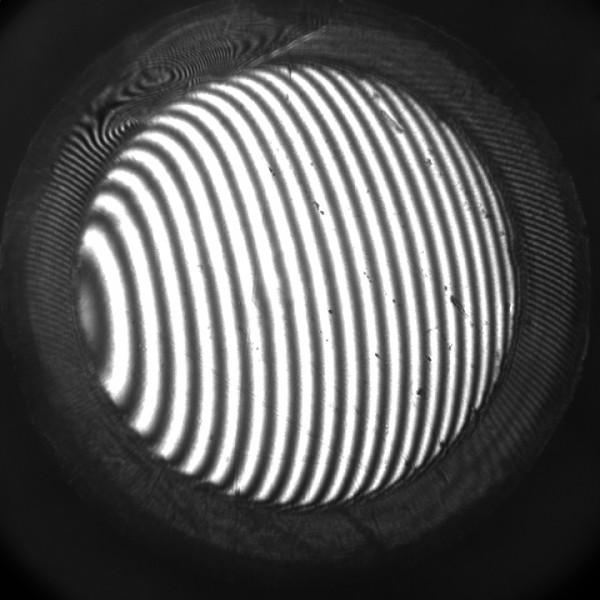

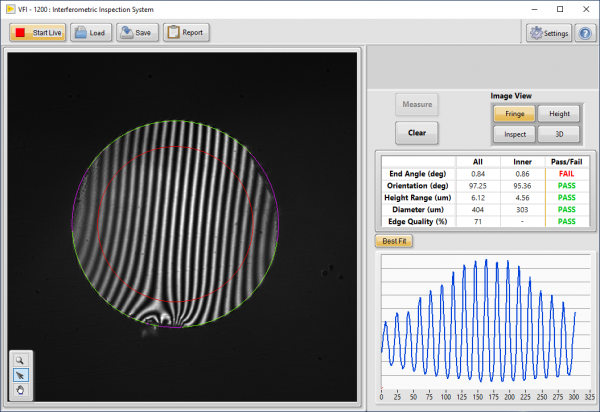

Over the years, the VFI has become well-established in the fiber industry due to its clean, sharp 2D images of the fiber. The 2D mode of operation allows for a real-time analysis of the fiber end face. Two different views are available in 2D mode:

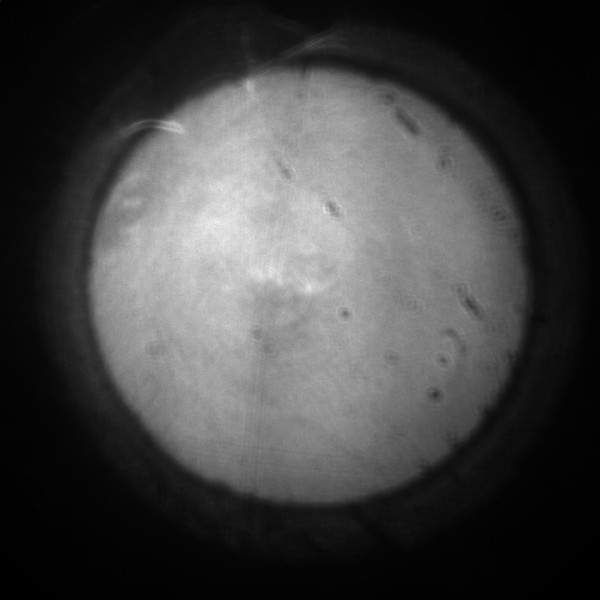

- Inspect view – provides a high quality image of the fiber for easy detection of damage or contamination to the fiber (cleave point impact, hackle, dust)

- Fringe view – high contrast and well-defined interference fringes allow the user to perform either a manual or fully automated analysis of the end face, to measure features such as the cleave angle and the amount of damage to the edge of the fiber

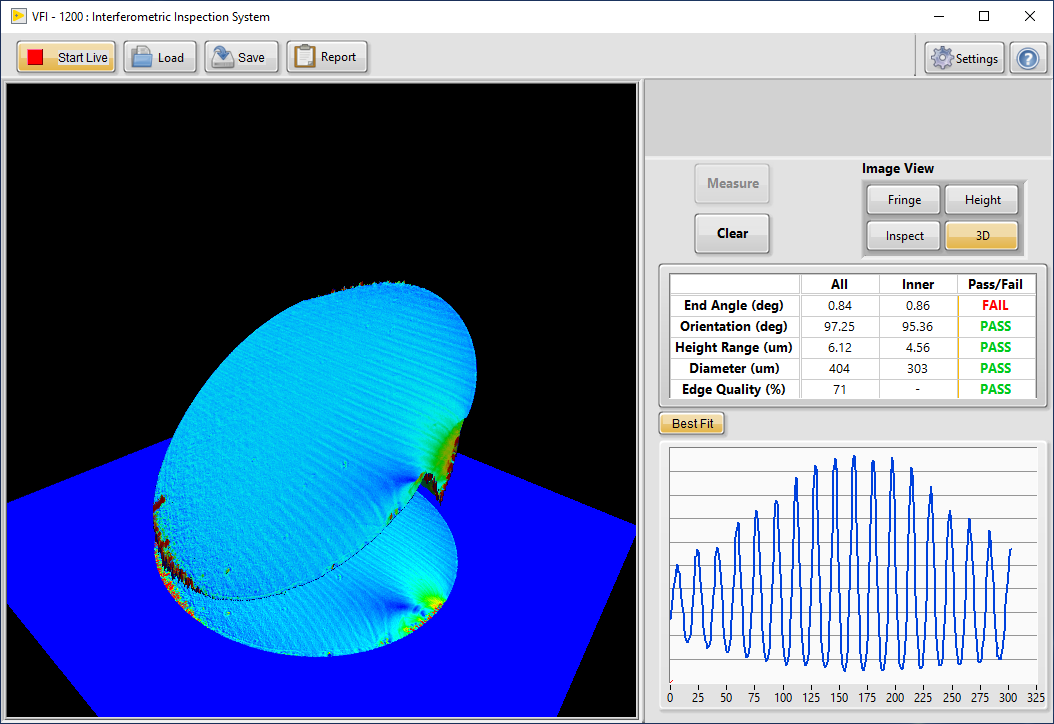

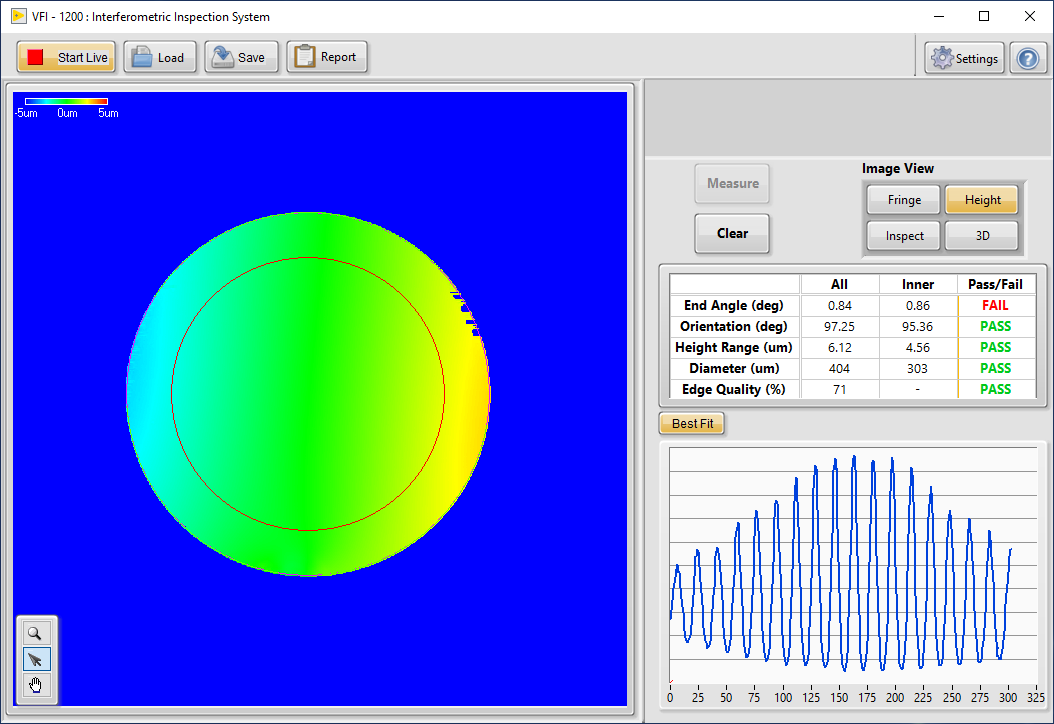

3D Mode

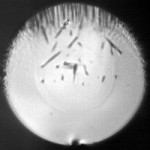

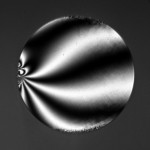

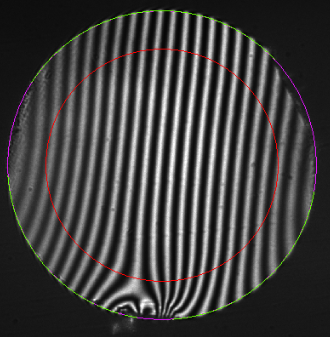

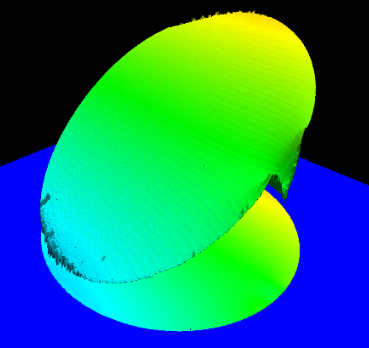

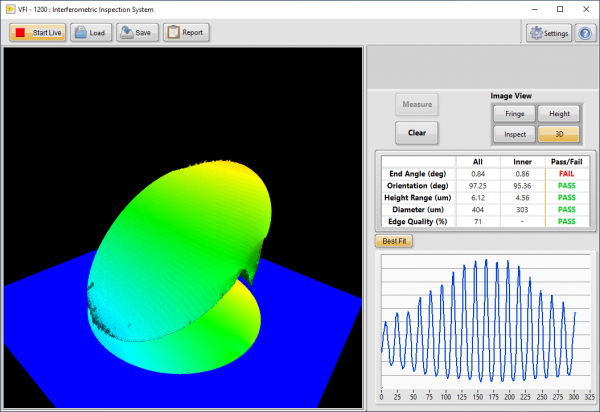

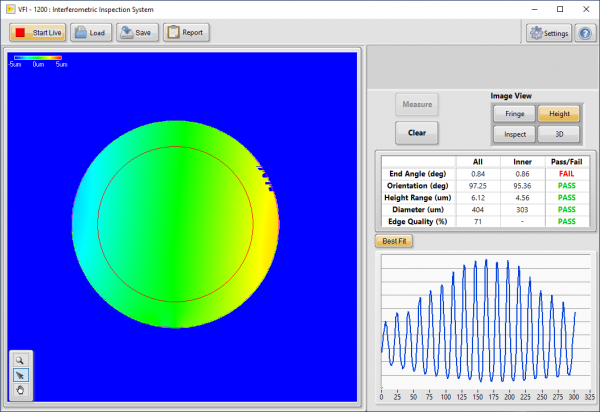

Users of the VFI are also able to create a 3D reconstruction of the fiber end face in just a matter of seconds at the click of a button. In 3D mode, two additional views are available:

- 3D Map – a three-dimensional view of the fiber, allowing the user to immediately visually analyse the surface profile of the fiber end face

- Height Map – a false colour map of the end face, with customisable scale, very useful in showing the change in cleave angle across the face of the fiber

Take control of your cleaving...

The VFI is used by customers around the world for a variety of applications in a wide range of industries, such as assessing cleave quality prior to high-strength splicing, cleaver maintenance, and production checks during the manufacture of critical optical assemblies such as fiber lasers.

Due to its user-friendly interface and ease of focusing, fully automated analysis of fiber end faces can be achieved in a matter of seconds, with minimal operator training needed.

Flexible software

The VFI comes with an efficient software package, providing the ability to analyse either a real-time 2D image of the fiber or a 3D reconstruction at the click of a button. Switching between Inspect view and Fringe view is also fully software controlled.

Users are able to grab and save images for later use, and previously stored images can be loaded for review. The report generator enables users to include up to 20 cleave images in one report along with comments. Users can also generate a .csv file giving height data for every pixel in the image. Other features include auto-optimisation of intensity, intensity line profile, edge damage estimation, angle orientation measurement, and measurement of radius of curvature.

Quality Images

The VFI-1200 combines its excellent image quality with a 1200 µm field of view, making it suitable for the analysis of fibers with cladding diameter anywhere from 80 µm to 1200 µm.

Four additional levels of digital zoom provide the ability to tailor the image to the fiber being analysed. The user can then further manipulate the image by zooming in further and rotating about the fiber in any direction, granting the user the power to focus on any specific areas of interest.

Fibre Holders and Accessories

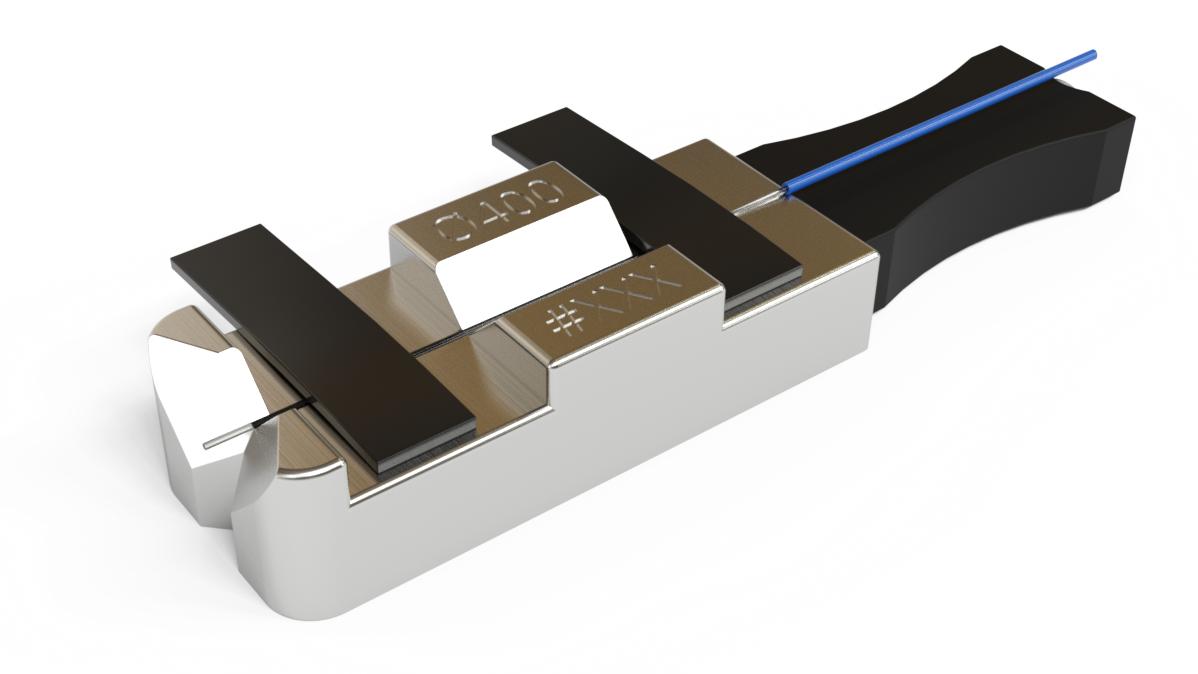

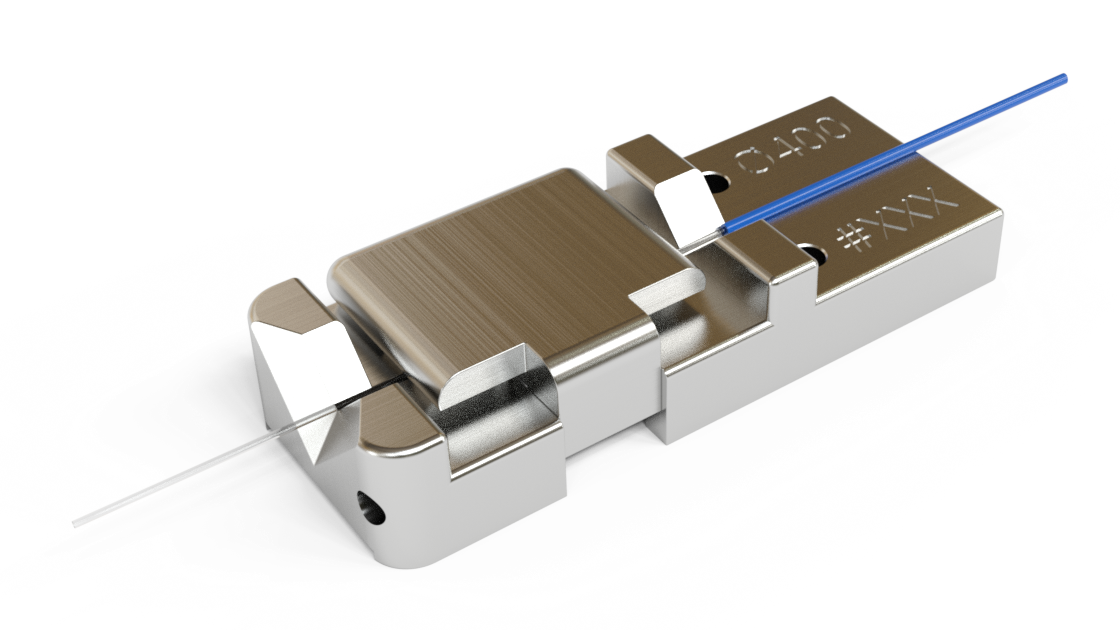

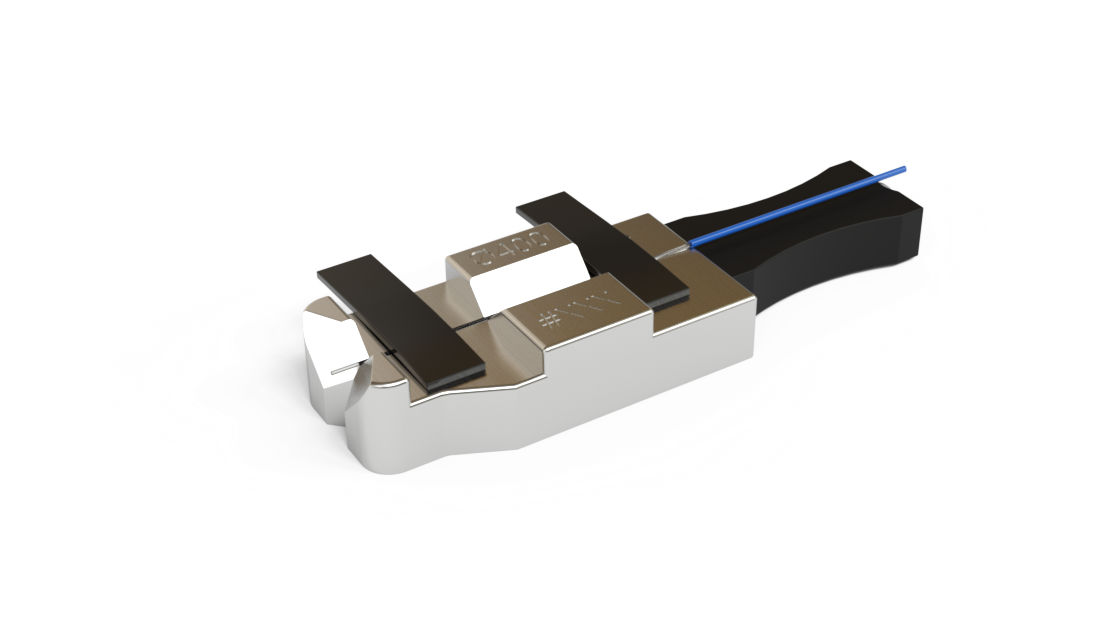

Classic-style Arden fiber holders

Arden Photonics classic-style fiber holders are well-established and have been the preferred holder for VFI users over the years. Our holders are precision engineered using stainless steel, ensuring the highest levels of accuracy and repeatability. They hold the fiber in a well-aligned V-groove using a soft but secure magnetic clamp, providing repeatable and reproducible results.

The holders come in a variety of sizes to accommodate a wide range of fiber diameters, up to 2mm.

Dual-style Arden fiber holders

Arden Photonics dual-style holders offer the same high levels of accuracy and repeatability as our classic holders, but add extra flexibility to the user experience. The dual-style holders can be used with the Arden Photonics FGC Fiber Geometry Systems as well as the VFI. They can also be used in most Fujikura cleavers and splicers, allowing the user to cleave, inspect, analyse and splice without ever having to touch the fiber!

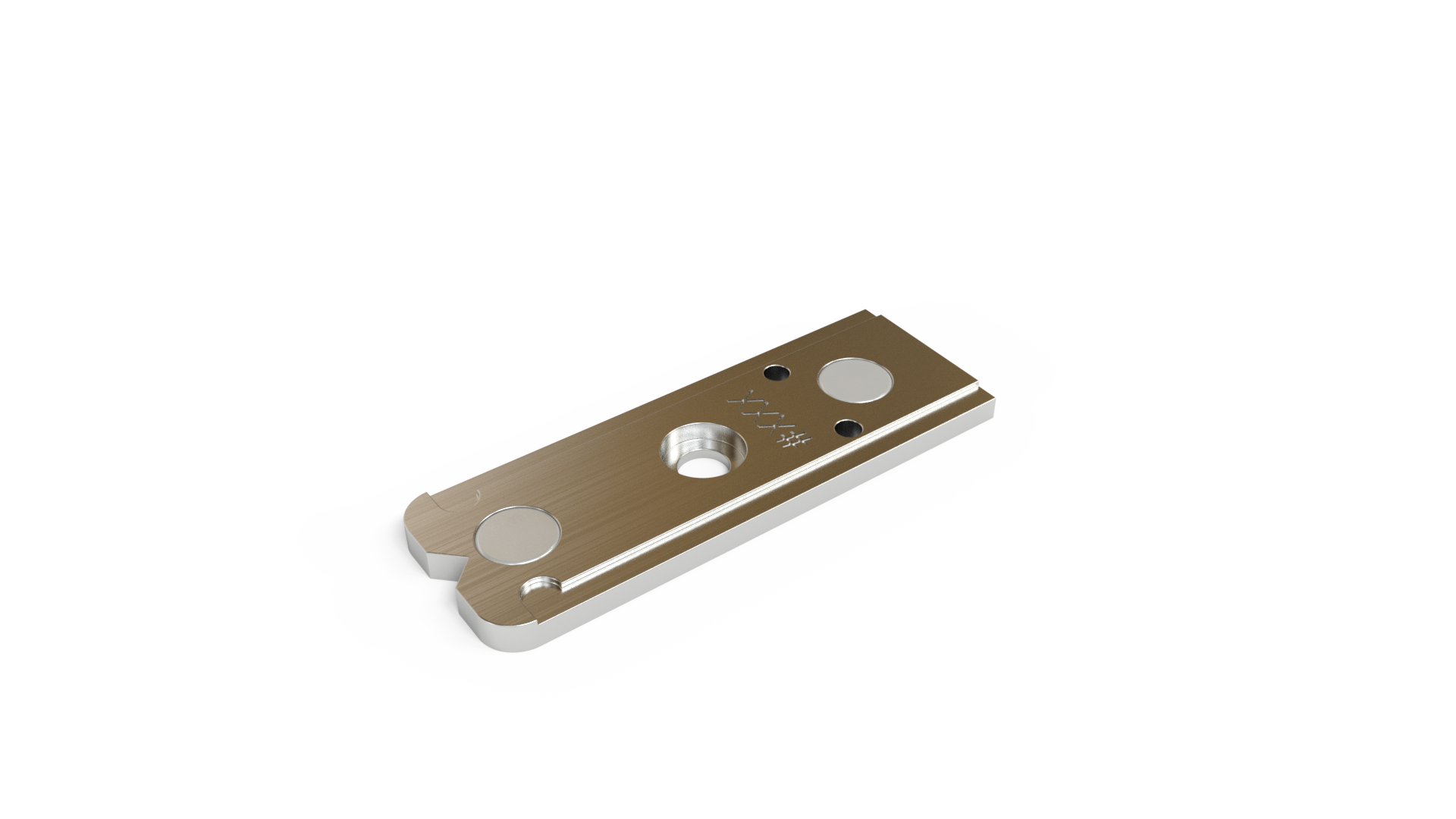

Adapter plates

We have a range of adapter plates available allowing our dual-style holders to be transferred to the VFI from a Fujikura cleaver, or from the VFI to a Fujikura splicer, without even having to touch the fiber.

Alternatively, the adapter plates allow standard Fujikura fiber holders to be used directly with the VFI. If you wish to use another type of holder then please contact us as we may be able to design an adapter plate to suit your needs.

Angled fiber holders

We also have angled fiber holders available, designed for use with fibers that have a large cleave angle. The angled holders hold the fiber at a specified angle in order to null the cleave angle so that an optimum platform is provided for analysing the features of the fiber end face.

Ferrule holders

We have a range of ferrule holders available to provide the user with the ability to analyse connectorised fibers and fibers in ferrules.

Most types of connector can be accommodated as we have ferrule holders for 1.25mm (LC), 2.5 mm (FC, SC, ST) and 3.2 mm (SMA) ferrules, as well as Size 16 ferrules.

Ribbon Fiber

The VFI-1200 can also be factory-fitted with an optional “ribbon stage”. The ribbon stage is a laterally adjustable stage designed for the quick and efficient 2D imaging of ribbon fibers.

After sales services

Contact Arden Photonics for information on our comprehensive packages (extended warranties, calibration programs, software upgrades, etc.) and per-incident services (repair, calibration, etc.)

The latest release of VFI software V6.3 is applicable to the VFI Interferometer series the VFI-200, VFI-1200 and VFI-2000. We strongly recommend all applicable Interferometers should be upgraded to the latest software for users to enjoy the new features and better user experience.

Please contact support@ardenphotonics.com to get a quotation.

| Feature | Benefit |

|---|---|

| Edge detection tool | Improved edge detection tool for non-circular fibers |

| Fringe counting | Improvements to fringe counting on domed surfaces such as connectors and polished fibers |

| 3D Reconstruction of height data | More intuitive visual analysis of the end-face, easier to perform cleave analysis |

| 3D representation of fiber end | More detailed analysis of the fiber end – easier to pick up defects |

Screen shots

|

|

|

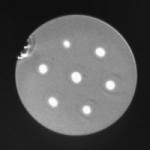

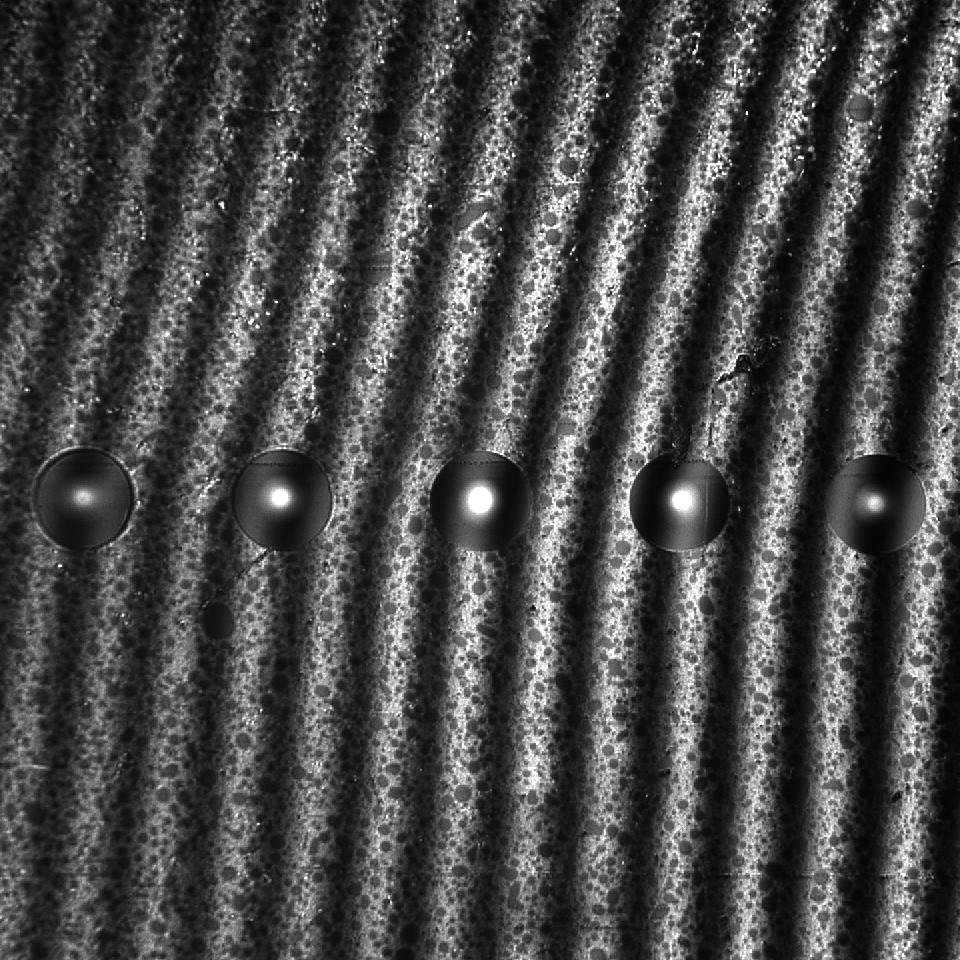

VFI v6.0 in “Fringe” mode VFI v6.0 in “Fringe” mode |

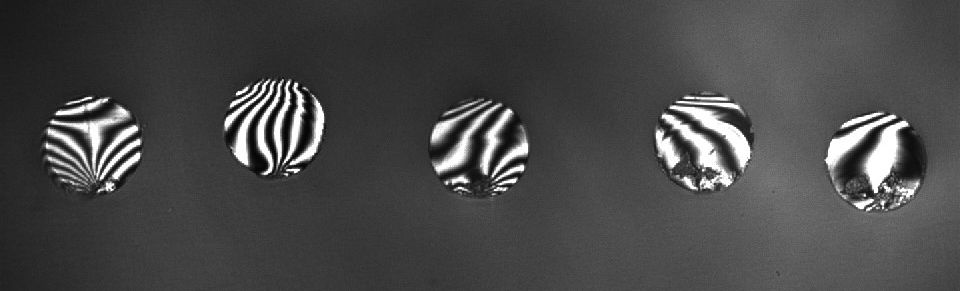

Images taken using the VFI Cleave Check Interferometer

| Optical | |

|---|---|

| Field of View | 1200 µm maximum with x1.5, x2, x3 and x6 digital zoom |

| Image sensor | 1/1.8 inch CMOS array, 12-bit, 6.4 MP |

| Camera sensor size | 3088 x 2076 px, 2.4 µm square pixels |

| LED wavelength | 525 nm |

| Measurement Capabilities | |

|---|---|

| Maximum measurable cleave angle (without using angled fiber holder)* | 2D mode: 8° 3D mode: 4° |

| Measurement time | 2D mode: real-time 3D mode: < 7 s |

| Image Quality | Fully resolves USAF Target to Level 7 minimum |

| Height Resolution | 0.01 µm |

| Physical | |

|---|---|

| Dimensions | 240(W) x 240(D) x 90(H) mm |

| Weight | 3 kg |

| Connection to computer | USB 3.0 (USB Type B to USB A; 1 m cable supplied) |

| Power supply | Via USB |

| Operating systems support | Windows 10/11 64bit |

| Computer requirements | 4 GB RAM; USB 3.0 port; 64bit |

| Operating temperature | 10 – 30°C |

* Maximum angle is stated for a fiber with 125 µm cladding diameter. Larger cleave angle can be measured using an angled fiber holder.

| Part number | Description |

|---|---|

| VFI-1200 | Interferometric inspection system for fibers with diameters from 80 to 1200 µm. Includes VFI-1200 optical unit; fiber holder for 400 µm fibers; VFI-FTK400 fiber samples; PC software; USB cable. Computer not included. |

| VFI-1200-RS | Interferometric inspection system for fibers with diameters from 80 to 1200 µm. Fitted with lateral stage for analysis of ribbons (2D only). Includes VFI-1200 optical unit; lateral adjustment stage; fiber holder for 400 µm fibers; VFI-FTK400 fiber samples; PC software; USB cable. Computer not included. |

| Fiber Holders | |

|---|---|

| VF-H0-xxx | Arden fiber holder for xxx µm fiber, perpendicular cleave |

| VF-H0-xxx-D | Dual-style Arden VFI fiber holder for xxxµm fiber, perpendicular cleave (requires adapter plate) |

| VF-H8-xxx | Arden fiber holder for xxx µm fiber, 8 degree cleave |

| VF-Annulus | 9-sided annulus used with fiber holder in order to present the fiber to the VFI at a range of integer angles (from 4 to 12 degrees) |

| Please note: for VFI-1200 standard holder sizes include 125, 200, 250, 400, 800 and 1000 with custom diameters available with extra charge. |

| Connector Holders | |

|---|---|

| VF-F125 | VFI holder for connector with 1.25 mm ferrule |

| VF-F250 | VFI holder for connector with 2.50 mm ferrule |

| VF-F16 | VFI holder for connector with # 16 style ferrule |

| VF-F320 | VFI holder for connector with 3.2 mm ferrule (SMA) |

| Adapter Plates | |

|---|---|

| VF-AP-3 | Adapter plate for use with dual-style Arden holders and Fujikura holders. For use with fiber protrusion of 3mm from end of holder |

| VF-AP-12.5 | Adapter plate for use with dual-style Arden holders and Fujikura holders. For use with fiber protrusion of 12.5mm from end of holder for direct use with FGC system or Fujikura cleavers and splicers (not suitable for fibers under 200µm in diameter) |

| VF-AP-C | Front-clamped adapter plate for use with dual-style Arden holders and Fujikura holders. For use with fiber protrusion of 12.5mm from end of holder for direct use with FGC system or Fujikura cleavers and splicers. Designed for use with 125µm fiber only. |

| Other options | |

|---|---|

| VFI-CC-01 | Rigid carrying case for VFI |

| VFI-UEW2 | VFI extended warranty covering parts and labour for 2 years from purchase, return to base. Cover excludes camera. |

| VFI-UEW3 | VFI extended warranty covering parts and labour for 3 years from purchase, return to base. Cover excludes camera. |

| VFI-UEW4 | VFI extended warranty covering parts and labour for 4 years from purchase, return to base. Cover excludes camera. |

| VFI-UEW5 | VFI extended warranty covering parts and labour for 5 years from purchase, return to base. Cover excludes camera. |

| VFI-FTK400 | VFI fiber samples, 400 μm diameter, for checking VFI-1200 alignment and calibration |

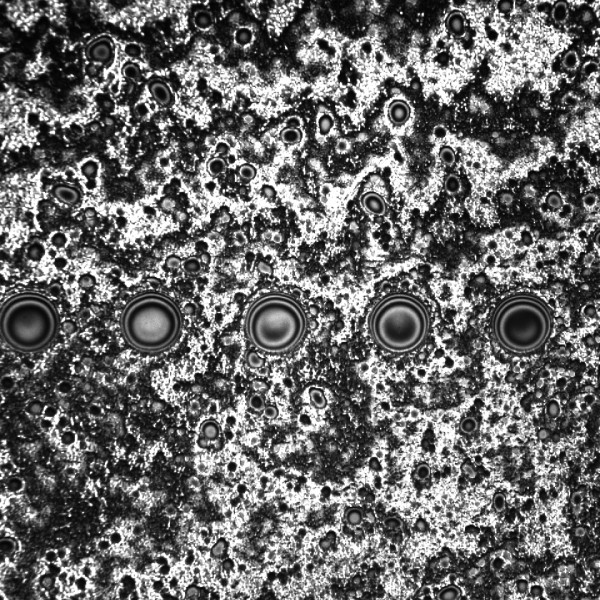

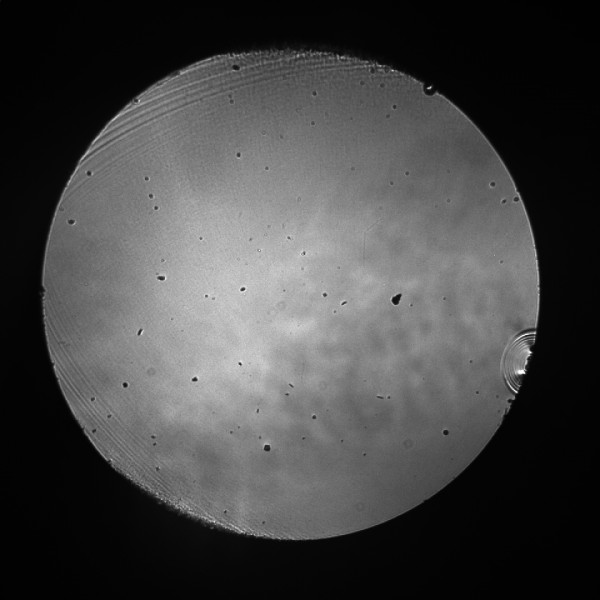

VFI v6.0 3D reconstruction

VFI v6.0 3D reconstruction VFI v6.0 3D representation of fiber end

VFI v6.0 3D representation of fiber end