The refractive index profiler of optical fiber is a key criterion of determining and optimising the fiber’s performance. It determines the propagation characteristics of light within the fiber. A well-designed fiber should have a uniform refractive index profile, which ensures that light propagates through the fiber without significant loss of signal. Even small variations in the refractive index profile can cause significant signal degradation, which can lead to reduced transmission distance and increased noise in the system.

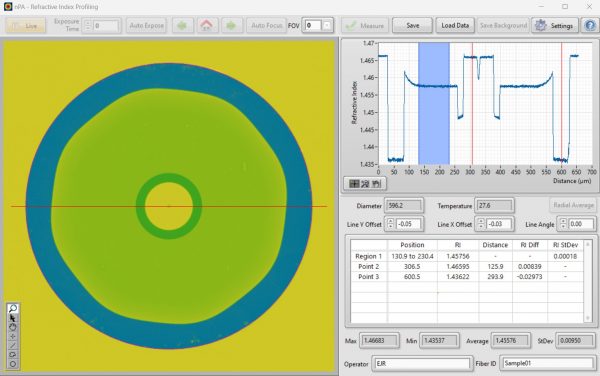

Measuring the refractive index profile of optical fiber is therefore critical to ensure that it meets the requirements of modern communication systems. Accurate measurements of the refractive index profile are necessary to optimise the performance of specialty fibers, such as multi-core fiber, triple cladding fiber, octagonal fiber, polarisation-maintaining fiber and photonic crystal fiber. However, measuring these fibers can be challenging.

Multi-core fiber:

Multi-core fiber is a type of optical fiber that contains multiple cores running down the length of the fiber. The fiber is used in applications where multiple channels of communication are required in a single fiber, such as in undersea communication cables, data centre interconnects or high-speed communication links. The refractive index profile of multi-core fiber is more complex than that of single-core fibers because each core must be carefully designed to ensure that the signal propagates through the fiber without interference between the cores. In addition, multi-core fibers can be designed with different refractive index profiles in each core, allowing more precise control of the signal propagation in each channel for improved signal quality and increased capacity in multi-core fiber communication systems. Accurate measurement of the refractive index profile is hard but crucial for optimising the performance of multi-core fibers.

Octagonal fiber:

Octagonal fiber is a specialty fiber used in sensing applications. It has an octagonal-shaped core, which provides increased sensitivity to external changes in temperature, pressure, or other environmental factors. The refractive index profile of octagonal fiber is critical to its performance, as even small variations can affect its sensitivity. Measuring the refractive index profile of octagonal fiber can be challenging due to its complex geometry.

Triple cladding fiber:

Triple cladding fiber is an optical fiber with three concentric layers of cladding surrounding the core. Sometimes it can be up to 600 µm in diameter. The outermost layer of cladding is typically made of a low refractive index polymer, whilst the inner two layers are made of high refractive index materials such as silica. The refractive index of the core is typically higher than that of the cladding, and it is important to measure the refractive index profile accurately.

Polarisation-maintaining fiber:

Polarisation-maintaining fiber is a specialty fiber used in applications where the polarisation state of the light is critical. The refractive index profile of the fiber is designed to maintain the polarisation state of the light as it propagates through the fiber. Accurate measurement of the refractive index profile is crucial to ensure that the polarisation-maintaining properties of the fiber are optimised for specific applications.

Photonic crystal fiber:

Photonic crystal fiber is a specialty fiber that uses a periodic array of air holes running down the length of the fiber to confine and guide light. The refractive index profile of photonic crystal fiber is highly complex and can be challenging to measure accurately.

Large optical fiber up to 600 µm:

Some applications, such as telecommunications, data centres and data centres, require using large optical fibers to provide a high-bandwidth, low-loss means of transmitting information over long distances. The performance of these fibers is closely linked to their refractive index profiles, which determine how light propagates through the fibers. Accurate measurement of the refractive index profile is crucial due to the increased likelihood of variations in the refractive index across the diameter of the fiber. Larger fibers also have higher signal power, which can lead to more significant signal degradation due to even small variations in the refractive index profile. However, most refractive index profilers in the market can measure fibers up to 400 µm only.

Refractive index profile is one of the most important parameters of an optical fiber. Accurate measurement and control of the refractive index profile ensure the performance of an optical fiber, increasing bandwidth and improving production yield rate. However, measuring large optical fibers and specialty fibers can be challenging.

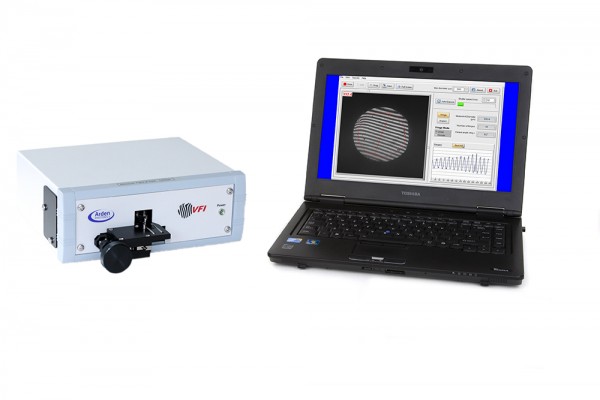

Arden Photonics’ latest nPA-600 Refractive Index Profiler is the quick, easy, and reliable way obtain the refractive index profile data to measure and verify specialty fiber design and manufacturing processes. It measures traditional circularly symmetric fibers and non-circularly symmetric fibers, such as polarisation maintaining, octagonal, and multi-core fibers, up to 600 µm in seconds. The nPA-600 comes with the nPA v2.0 software which boosts system performance and improves user experience, and the API allows the nPA-600 to integrate to other systems seamlessly.

If you have any measurement requirement for your fibers, please feel free to speak to our team of passionate optical fiber measurement specialists.

To find out more about Arden’s nPA-600 Refractive Index Profiler: https://www.ardenphotonics.com/products/npa-600/